In the framework of the Leader XI project, the first in Poland cold pressing through an axial channel (ECAP) of titanium grade 2 has been carried out. So far, the ECAP process for this material has been carried out only in foreign centres.

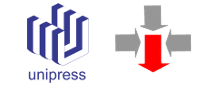

In this method, the tested material is squeezed with a piston through two channels of equal cross-sections connected at an angle of 2φ, generating plastic deformation in the material as a result of pure shear occurring in the deformation zone. ECAP offers the possibility of generating a large plastic deformation in the material by repeatedly the process with a constant plastic deformation in each operation. For the most commonly used 90° channel, the actual strain in one operation is ε = 1.15 which for commonly used repetition rates between 2 and 12 gives a cumulative strain range of ε = 2.3 – 13.9.

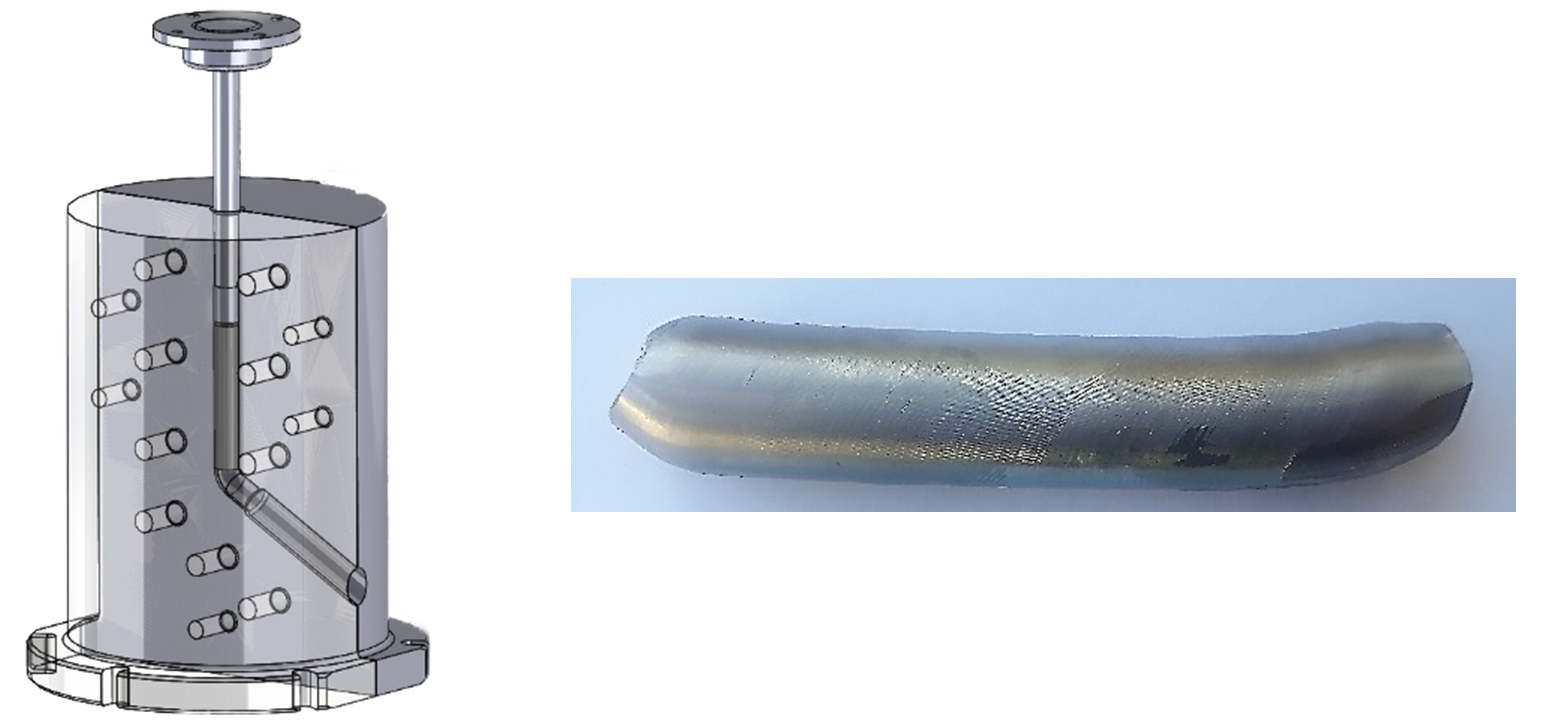

The ECAP chamber designed and constructed within the Leader XI project has the angle 2φ = 120° which allows to generate the strain in one step of the process ε = 0.66. The scheme of the process and a picture of titanium deformed in the Laboratory of Plastic Deformation Under High Pressure are presented in Fig. 1.

In this method, the tested material is squeezed with a piston through two channels of equal cross-sections connected at an angle of 2φ, generating plastic deformation in the material as a result of pure shear occurring in the deformation zone. ECAP offers the possibility of generating a large plastic deformation in the material by repeatedly the process with a constant plastic deformation in each operation. For the most commonly used 90° channel, the actual strain in one operation is ε = 1.15 which for commonly used repetition rates between 2 and 12 gives a cumulative strain range of ε = 2.3 – 13.9.

The ECAP chamber designed and constructed within the Leader XI project has the angle 2φ = 120° which allows to generate the strain in one step of the process ε = 0.66. The scheme of the process and a picture of titanium deformed in the Laboratory of Plastic Deformation Under High Pressure are presented in Fig. 1.

Fig. 1. ECAP process diagram and titanium grade 2 specimen after deformation