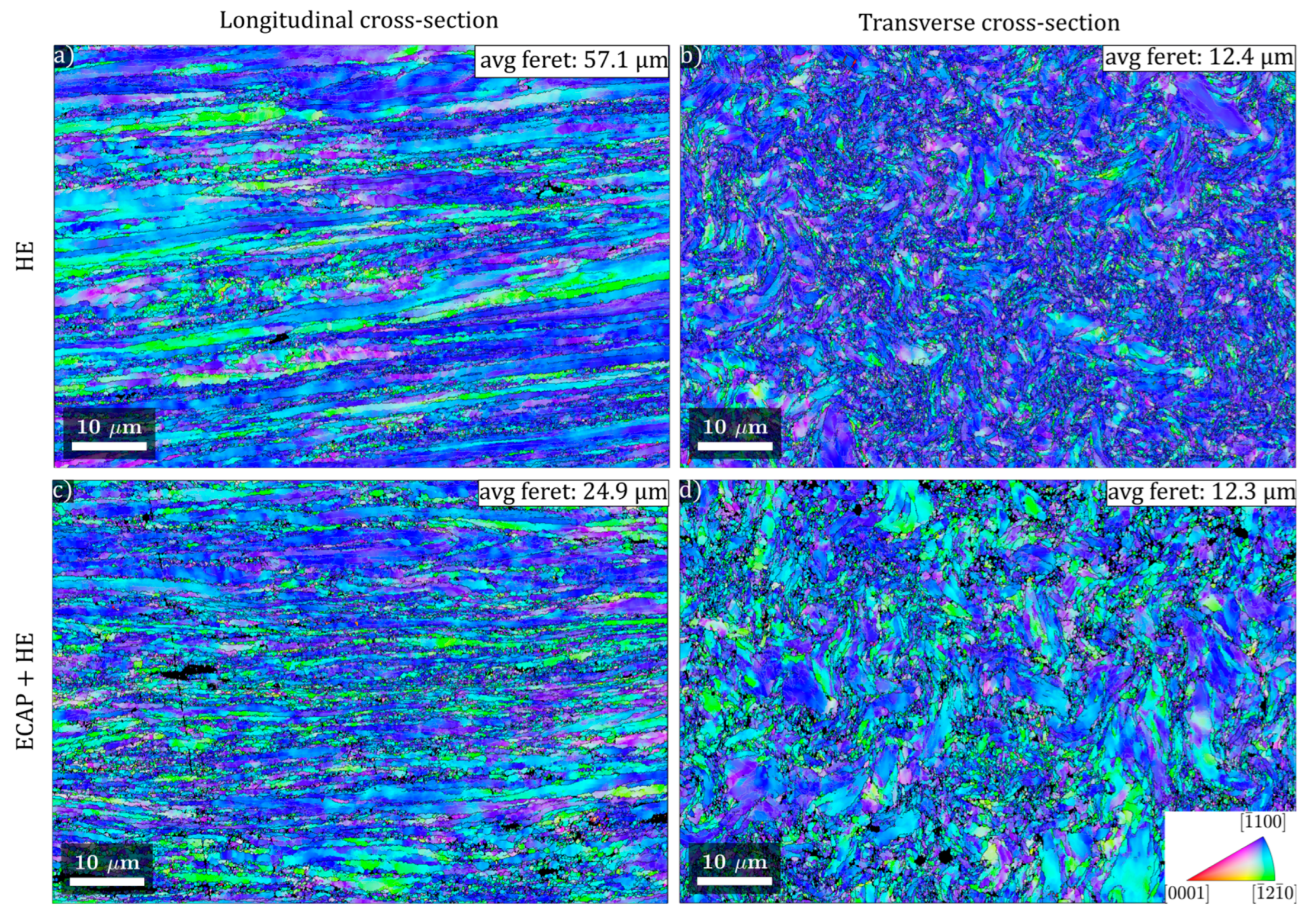

Hydrostatic extrusion (HE) of pure titanium effectively boosts its mechanical strength and wear resistance without the need to add alloying elements such as Al, V or Nb. It strongly refines the microstructure but creates anisotropy due to fibrous grains aligned with the extrusion direction, limiting its use in components subjected to forces perpendicular to these fibers.

A recent study from our Institute addresses this issue by applying equal-channel angular pressing (ECAP) before HE. The Institute of High Pressure Physics (IHPP) PAS developed an ECAP station for room-temperature deformation, avoiding heating that reduces strain hardening. ECAP of titanium at ambient temperature is rare in literature, and combining ECAP with HE for titanium remains largely unexplored. Recent study by M. Kulczyk et al. Using a Combination of ECAP and HE Processes to Produce Isotropic Ultrafine-Grained Titanium Materials 2025, 18, 5194 presents an optimized ECAP + HE process that produces ultrafine-grained/nanocrystalline titanium with isotropic mechanical properties. Structural changes were analyzed using TEM, statistical image analysis, and SEM-EBSD techniques.

Resolving the strong anisotropy in ultrafine-grained titanium unlocks new prospects for its commercial use, especially in medical implants.

Inverse pole figure (IPF) maps of TiGr2 microstructure after hydrostatic extrusion (HE) (a,b) and combined ECAP + HE (c,d) processing.

Recent Comments